{{Short description|Type of retail packaging}}

{{Short description|Type of retail packaging}}

{{multiple issues|

{{multiple issues|

{{notability|date=July 2025}}

{{notability|date= 2025}}

{{peacock|date=July 2025}}

{{|date= 2025}}

{{copyedit|date=July 2025}}

}}

}}

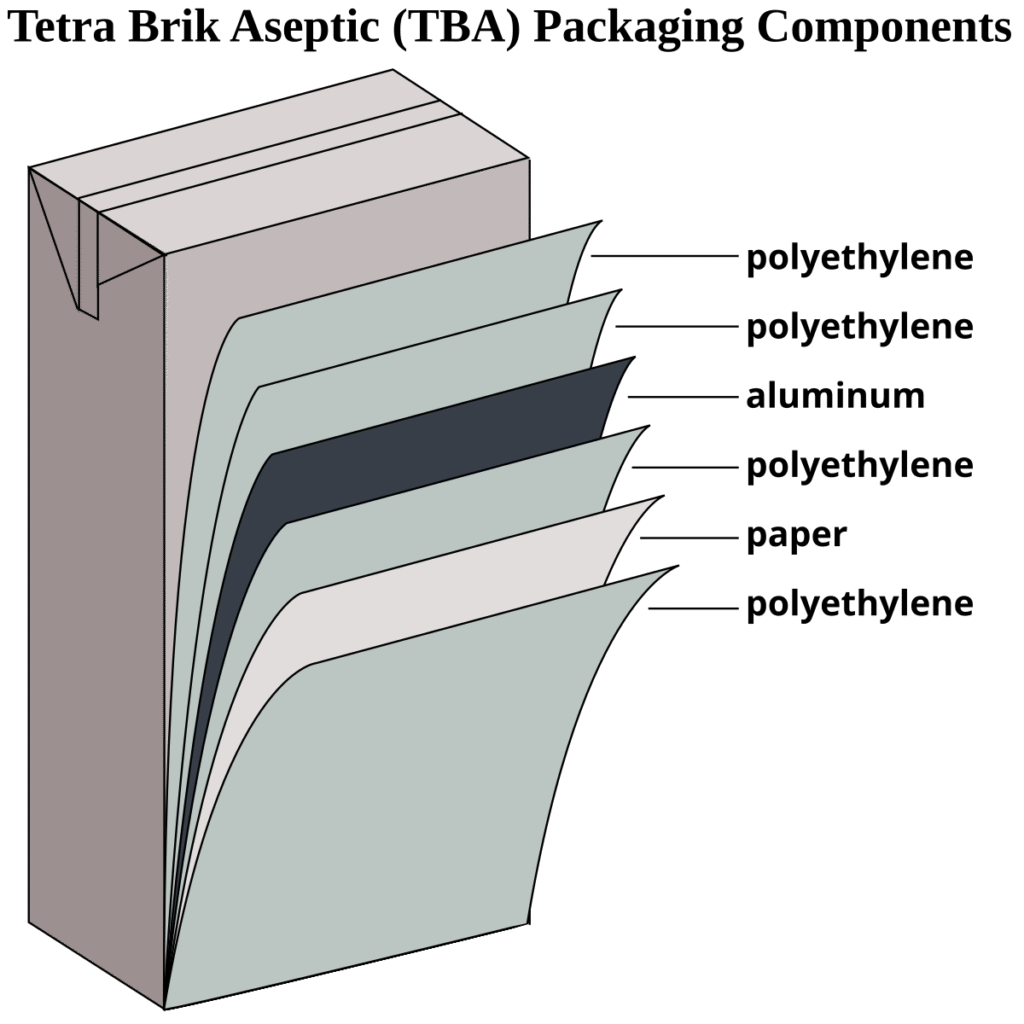

[[File:TBA_packaging_components.svg|thumb|244x244px|Multilayered beverage cartons]]

[[File:TBA_packaging_components.svg|thumb|244x244px| beverage cartons]]

”’Multilayered packaging”’ (commonly referred to as ”multilayer packaging”) refers to [[Composite material|composite materials]] made from two or more distinct layers, where each layer is selected for its specific protective or functional properties. Common forms include films, pouches, aseptic cartons, bottles, and tubes.<ref name=”:7″>{{Cite journal |last1=Mulakkal |first1=M.C. |last2=Ekins |first2=C. |last3=Wen |first3=J. |last4=Ramchandran |first4=R. |last5=Taylor |first5=A.C. |last6=Pimenta |first6=S. |last7=Charalambides |first7=M.N. |date=2025-06-16 |title=Evaluation of Recyclable Multilayer Packaging Designs Utilising Controlled Interlayer Adhesion |journal=Experimental Mechanics |language=en |doi=10.1007/s11340-025-01200-2 |issn=1741-2765|doi-access=free }}</ref>

Examples of specific properties of layers in a multilayered packaging are heat [[Food packaging sealing techniques|sealability]], [[Ultimate tensile strength|tensile strength]], or enhanced gas and light barrier properties. Examples of applications of multilayered packaging are [[sustainability]], reduced [[environmental impact]], and extended shelf life.<ref name=”:8″>{{Cite journal |last1=Schmidt |first1=Jannick |last2=Grau |first2=Laura |last3=Auer |first3=Maximilian |last4=Maletz |first4=Roman |last5=Woidasky |first5=Jörg |date=2022-04-29 |title=Multilayer Packaging in a Circular Economy |journal=Polymers |language=en |volume=14 |issue=9 |pages=1825 |doi=10.3390/polym14091825 |issn=2073-4360 |pmc=9103501 |pmid=35566994 |doi-access=free}}</ref>

of layers [[ ]], [[ ]], and . of .<ref name=”:8″>{{Cite journal |last1=Schmidt |first1=Jannick |last2=Grau |first2=Laura |last3=Auer |first3=Maximilian |last4=Maletz |first4=Roman |last5=Woidasky |first5=Jörg |date=2022-04-29 |title=Multilayer Packaging in a Circular Economy |journal=Polymers |volume=14 |issue=9 |pages=1825 |doi=10.3390/polym14091825}}</ref>

[[Polyethylene|Polyethylene (PE)]], [[Polyethylene terephthalate|polyethylene terephthalate (PET)]], [[Polyamide|polyamide (PA)]], [[Ethylene vinyl alcohol|ethylene vinyl alcohol (EVOH)]], [[aluminium foil]], and [[paperboard]] are some of the most common materials used.

== History ==

== History ==

[[File:Tetra_Pak_boy_with_Tetra_Classic,_Italy.jpg|left|thumb|Early adoption of aseptic cartons in Europe, 1960s]]

[[File:Tetra_Pak_boy_with_Tetra_Classic,_Italy.jpg|left|thumb|Early aseptic cartons , 1960s]]

The development of multilayer packaging materials began in the mid-20th century, in order to address the limitations of [[single-layer materials]], which often did not meet performance requirements, particularly in protecting chemically-sensitive products.<ref name=”:11″>{{Cite web |title=Our heritage |url=https://www.tetrapak.com/about-tetra-pak/who-we-are/heritage |access-date=2025-07–10 |website=www.tetrapak.com |language=en}}</ref>

packaging in the mid-20th century to the of single-layer materials.<ref name=”:11″>{{Cite web |title=Our heritage |url=https://www.tetrapak.com/about-tetra-pak/who-we-are/heritage |access-date=2025– |website=www.tetrapak.com |=}}</ref>

One of the earliest examples of a multilayered packaging are [[Aseptic carton|aseptic cartons]] by [[Tetra Pak]], developed in the early 1960s, which used [[Lamination|laminated]] layers of paperboard, [[polyethylene]], and [[Aluminium foil|aluminum foil]].<ref name=”:11″ />

In the 1970s and 1980s, companies began using multilayer films to make vacuum-sealed pouches and heat-safe bags for ready-to-eat meals and foods with a long-term shelf life. Multilayer containers, like plastic bottles with special layers that keep out oxygen, were also developed during this timeframe. Applications of these items included [[Sauce|sauces]], [[Spice|spices]], and [[medicines]].<ref name=”:12″>{{Cite book |last=Singh |first=Sonika |url=https://www.lunduniversity.lu.se/lup/publication/9020499 |title=Recyclability by Design for Multilayer Plastic Flexible Packaging |date=2020 |publisher=Lund University |location=Sweden |pages=9–13}}</ref>

During the 1990s, multilayer packaging had become common around the world. New advances in how the layers were joined, shaped, and glued together made multilayer packaging stronger, cheaper, and increased the number of potential applications further.<ref name=”:12″ />

== Types ==

== Types ==

Multilayer packaging can look different depending on how it is used, what materials are combined, and how much protection is needed to keep food or medicine safe.<ref>{{Cite journal |last1=Tamizhdurai |first1=P. |last2=Mangesh |first2=V. L. |last3=Santhosh |first3=S. |last4=Vedavalli |first4=R. |last5=Kavitha |first5=C. |last6=Bhutto |first6=Javed Khan |last7=Alreshidi |first7=Maha Awjan |last8=Yadav |first8=Krishna Kumar |last9=Kumaran |first9=R. |date=2024-04-01 |title=A state-of-the-art review of multilayer packaging recycling: Challenges, alternatives, and outlook |url=https://www.sciencedirect.com/science/article/pii/S0959652624008503 |journal=Journal of Cleaner Production |volume=447 |article-number=141403 |doi=10.1016/j.jclepro.2024.141403 |bibcode=2024JCPro.44741403T |issn=0959-6526|url-access=subscription }}</ref>

Multilayer packaging and .<ref>{{Cite journal |last1=Tamizhdurai |first1=P. |last2=Mangesh |first2=V. L. |last3=Santhosh |first3=S. |last4=Vedavalli |first4=R. |date=2024-04-01 |title=A state-of-the-art review of multilayer packaging recycling: Challenges, alternatives, and outlook |journal=Journal of Cleaner Production |volume=447 |article-number=141403 |doi=10.1016/j.jclepro.2024.141403}}</ref>

=== Multi-wall paper sacks ===

These sacks are made from several layers of strong [[kraft paper]], with each layer having a different thickness. Multi-layer paper sacks are becoming more popular in industries like cement, medicine, and fertilizer. To protect contents from moisture, the inner or outer layer is often coated with a thin layer of plastic ([[polyethylene]]; PE).<ref>{{Cite web |title=Products |url=https://turkkraft.com/en/products |access-date=2025-07-11 |website=turkkraft.com |language=en}}</ref>

* ”’Multi-wall paper sacks”’ – layers of kraft paper, sometimes with polyethylene, for cement, fertilizer, and bulk foods.

=== Laminated-cartons ===

* ”’Laminated cartons”’ – paperboard with aluminium foil and plastics, used for milk, juice, and syrups.

These packages are often used in the paint industry, in Tetra Paks for [[milk]], [[fruit juice]], and [[Syrup|syrups]], and in making medicines. Common layer combinations include:<ref>{{Cite web |title=Multilayer Films |url=http://polymerdatabase.com/Films/Multilayer%20Films.html |access-date=2020-04-16 |website=polymerdatabase.com}}</ref>

* ”’Plastic bottles and tubes”’ – combinations such as PET/EVOH/PE, used for sauces, juices, and cosmetics.

* ”’High-barrier pouches”’ – flexible laminates with PA, EVOH, or oxide coatings, used for sterilized or ready-to-eat meals.

== Food packaging ==

* Paper with aluminum foil and [[low-density polyethylene]] (LDPE), a flexible type of plastic

[[File:Multilayer_Beverage_packaging_and_Environmental_barrier.jpg|thumb|440x440px|Example of multilayer food package with barrier layers]]

* Aluminum foil with paper and LDPE

Multilayer systems are widely used for [[food preservation]] because they block oxygen, light, and moisture. EVOH is often used as an oxygen barrier, while polyolefins provide moisture resistance.<ref>{{Cite journal |last1=Bauer |first1=Anna-Sophia |last2=Tacker |first2=Manfred |date=2021-11-05 |title=Recyclability and Redesign Challenges in Multilayer Flexible Food Packaging—A Review |journal=Foods |volume=10 |issue=11 |pages=2702 |doi=10.3390/foods10112702}}</ref>

* PE, a common plastic, with aluminum foil and paper

Another application is [[modified atmosphere packaging]] (MAP), where air is replaced by controlled gases such as nitrogen or carbon dioxide to slow microbial growth.<ref>{{Cite journal |last1=Seier |first1=Martina |last2=Archodoulaki |first2=Vasiliki-Maria |date=2023-07-06 |title=Prospects for Recyclable Multilayer Packaging: A Case Study |journal=Polymers |volume=15 |issue=13 |pages=2966 |doi=10.3390/polym15132966}}</ref>

* PET, a strong plastic often used in bottles, with aluminum foil and LDPE

== Manufacturing ==

=== Plastic bottles and tubes ===

Three main processes are used:<ref>{{Cite journal |last1=Alreshidi |first1=Maha Awjan |last2=Yadav |first2=Krishna Kumar |date=2025-07-01 |title=Advancements in the production methods and recycling of multilayer plastics with sustainable applications: A comprehensive review |journal=Chemical Engineering Journal |volume=515 |article-number=163633 |doi=10.1016/j.cej.2025.163633}}</ref>

Many plastic bottles and tubes are made with several layers of different plastics. For example, some use PET, EVOH, and PE. These composite bottles are used for storing sauces, juices, and cosmetics. In this design, EVOH keeps out oxygen so the product stays fresh, while PE or [[polypropylene]] (PP) make the container strong and easy to seal.<ref>{{Cite web |title=University of Pittsburgh |url=https://www.newplasticseconomy.org/innovation-prize/winners/university-of-pittsburgh |access-date=2020-04-16 |website=New Plastics Economy (en-GB)}}</ref>

* ”’Coextrusion”’ – simultaneous extrusion of polymers, often with tie layers.

* ”’Lamination”’ – bonding of prefabricated films, foils, or paper layers with adhesives or heat.

* ”’Coating”’ – applying functional layers, such as metallization or oxide coatings, onto substrates.

== End-of-life ==

=== High-barrier flexible pouches ===

Multilayer packaging provides strong barriers but is difficult to recycle because of its mixed-material structure. Less than 5% is currently recycled at scale, with most waste incinerated or landfilled.<ref>{{Cite journal |last1=Hahladakis |first1=John N. |last2=Iacovidou |first2=Eleni |date=2018-07-15 |title=Closing the loop on plastic packaging materials: What is quality and how does it affect their circularity? |journal=Science of the Total Environment |volume=630 |pages=1394–1400 |doi=10.1016/j.scitotenv.2018.02.330}}</ref>

These pouches are often used for ready-to-eat and sterilized foods. They are made with special layers, such as PA, EVOH, or thin [[silicon oxide]] (SiOx) coatings. These layers make the pouches tough so they don’t tear easily, and they also block gases like oxygen, preventing spoilage.<ref>{{Cite journal |last1=Turan |first1=Deniz |last2=Keukens |first2=Barbera M. |last3=Schifferstein |first3=Hendrik N. J. |date=2024 |title=Food packaging technology considerations for designers: Attending to food, consumer, manufacturer, and environmental issues |url=https://onlinelibrary.wiley.com/doi/abs/10.1111/1541-4337.70058 |journal=Comprehensive Reviews in Food Science and Food Safety |language=en |volume=23 |issue=6 |pages=e70058 |doi=10.1111/1541-4337.70058 |pmid=39530596 |issn=1541-4337}}</ref>

Research is exploring solvent-based separation, compatibilizers, and enzymatic depolymerization of PET.<ref>{{Cite journal |last1=Soares |first1=Camila Távora de Mello |date=2022-01-01 |title=Recycling of multi-material multilayer plastic packaging: Current trends and future scenarios |journal=Resources, Conservation and Recycling |volume=176 |article-number=105905 |doi=10.1016/j.resconrec.2021.105905}}</ref>

== Multilayer food packaging ==

[[File:Multilayer_Beverage_packaging_and_Environmental_barrier.jpg|thumb|440x440px|Multilayer food package having 6 layers with functional barriers to the environment]]

{{See also|Food packaging}}

[[Food preservation]] is a complex process that relies heavily on advanced packaging technologies, which is why multilayered structures are an essential part of the food industry. These systems are engineered based on the specific properties of the product to enhance barrier properties against [[oxygen]], [[moisture]], and [[light]], while preserving product integrity, shelf life, and storage stability.<ref>{{Cite journal |last1=Bauer |first1=Anna-Sophia |last2=Tacker |first2=Manfred |last3=Uysal-Unalan |first3=Ilke |last4=Cruz |first4=Rui M. S. |last5=Varzakas |first5=Theo |last6=Krauter |first6=Victoria |date=2021-11-05 |title=Recyclability and Redesign Challenges in Multilayer Flexible Food Packaging—A Review |journal=Foods |language=en |volume=10 |issue=11 |pages=2702 |doi=10.3390/foods10112702 |pmid=34828983 |doi-access=free |issn=2304-8158 |pmc=8624454}}</ref> Multilayered systems are fine-tuned to match the physicochemical characteristics of the food product. For instance, oxygen-sensitive items are typically stored inside packaging with an EVOH layer because of its exceptionally low [[oxygen transmission rate]] (< 1 cm<sup>3</sup>.m<sup>-2</sup>.day<sup>-1</sup>.atm<sup>-1</sup> in dry conditions). In contrast, [[polyolefin]] layers are externally incorporated to enhance water vapor resistance and [[Sealing wax|sealing]] efficacy. Paperboard or PET is often included to improve mechanical strength, printability, and [[stiffness]].<ref name=”:7″ />

Multilayer films used in [[Modified atmosphere|modified atmosphere packaging]] (MAP) account for approximately 30% of the food packaging sector.<ref name=”:4″>{{Cite journal |last1=Seier |first1=Martina |last2=Archodoulaki |first2=Vasiliki-Maria |last3=Koch |first3=Thomas |last4=Duscher |first4=Bernadette |last5=Gahleitner |first5=Markus |date=2023-07-06 |title=Prospects for Recyclable Multilayer Packaging: A Case Study |journal=Polymers |language=en |volume=15 |issue=13 |pages=2966 |doi=10.3390/polym15132966 |pmid=37447609 |doi-access=free |issn=2073-4360 |pmc=10346915}}</ref> MAP is a [[Hermetic seal|hermetically sealed]] multilayer material system that prolongs the shelf life of [[Decomposition|perishable]] goods by creating a modified gaseous environment. In this, the package is flushed with different mixtures of gases ([[Nitrogen|N<sub>2</sub>]]/[[Carbon dioxide|CO<sub>2</sub>]]/[[Oxygen|O<sub>2</sub>]]) that slow microbial spoilage and oxidation.<ref name=”:4″ /><ref>{{Citation |last1=Vakkalanka |first1=M. Sr. |title=7 – Emerging packaging technologies for fresh produce |date=2012-01-01 |work=Emerging Food Packaging Technologies |pages=109–133 |editor-last=Yam |editor-first=Kit L. |url=https://www.sciencedirect.com/science/article/pii/B9781845698096500075 |access-date=2025-07-10 |series=Woodhead Publishing Series in Food Science, Technology and Nutrition |publisher=Woodhead Publishing |doi=10.1533/9780857095664.1.109 |isbn=978-1-84569-809-6 |last2=D’Souza |first2=T. |last3=Ray |first3=S. |last4=Yam |first4=K. L. |last5=Mir |first5=N. |editor2-last=Lee |editor2-first=Dong Sun|url-access=subscription }}</ref> Moreover, sealing efficacy is crucial for maintaining product integrity and preventing degradation.<ref name=”:5″>{{Cite journal |last1=Soares |first1=Camila Távora de Mello |last2=Ek |first2=Monica |last3=Östmark |first3=Emma |last4=Gällstedt |first4=Mikael |last5=Karlsson |first5=Sigbritt |date=2022-01-01 |title=Recycling of multi-material multilayer plastic packaging: Current trends and future scenarios |journal=Resources, Conservation and Recycling |volume=176 |article-number=105905 |doi=10.1016/j.resconrec.2021.105905 |bibcode=2022RCR…17605905S |issn=0921-3449|doi-access=free }}</ref>

Multilayer food packaging is categorized into two primary types, flexible and rigid, according to material, physical form, and composition, with each kind optimized through specific production methods.<ref name=”:5″ />

== Diffusion-controlled barrier performance of multilayer systems ==

Multilayer packaging protects food by regulating the movement of gases, vapors, and contaminants via barrier layers. The protective mechanism is based on [[diffusion]] and [[solubility]] control, as stated by [[Fick’s laws of diffusion|Fick’s first law]]:<ref>{{Cite journal |last1=Zeman |first1=Stanislav |last2=Kubík |first2=L’ubomír |date=2007-11-01 |title=Permeability of Polymeric Packaging Materials |journal=Technical Sciences |volume=10 |issue=–1 |pages=33–34 |doi=10.2478/v10022-007-0004-6 |issn=1505-4675|doi-access=free }}</ref>

: <math>F = -D \frac{dC}{dx}</math>

Where F represents the [[flux]] (quantity of gas per unit area per unit time), D denotes the [[diffusion coefficient]], and <math>\frac{dC}{dx}</math> is the change in [[concentration]] over the thickness of the film. The total [[Permeability (porous media)|permeability]] P of a layer is the diffusion coefficient times the solubility:<ref>{{Cite journal |last1=VaÅ¡ko |first1=Karol |last2=Noller |first2=Klaus |last3=Mikula |first3=Milan |last4=Amberg-Schwab |first4=Sabine |last5=Weber |first5=Ulrike |date=2009-06-01 |title=Multilayer coatings for flexible high-barrier materials |journal=Open Physics |language=en |volume=7 |issue=2 |pages=371–378 |doi=10.2478/s11534-009-0056-2 |bibcode=2009CEJPh…7..371V |issn=2391-5471|doi-access=free }}</ref>

: <math>P = D \cdot S</math>

In multilayer systems, the effective permeability can be determined using a series resistance model:<ref>{{Cite journal |last1=Vercasson |first1=Allison |last2=Gaucel |first2=Sébastien |last3=Gontard |first3=Nathalie |last4=Angellier-Coussy |first4=Hélène |last5=Guillard |first5=Valérie |date=2025-09-01 |title=Applicability of the series resistance model in predicting the permeability of coated papers to oxygen and water vapor: importance of data quality and associated metadata |journal=Polymer Testing |volume=150 |article-number=108907 |doi=10.1016/j.polymertesting.2025.108907 |issn=0142-9418|doi-access=free }}</ref>

: <math>\frac{1}{P_\text{total}} = \sum_{i=1}^{n} \frac{l_i}{P_i}</math>

Where <math display=”inline”>l_i</math> and <math display=”inline”>P_i</math> are the thickness and permeability of each layer. High-barrier polymers like EVOH do not let much oxygen through because they are [[Crystallinity|crystalline]] and polar. However, EVOH is sensitive to moisture; when the [[Humidity|relative humidity]] is high, its barrier degrades as it [[Plasticizer|plasticizes]].<ref>{{Cite journal |last1=Wu |first1=Feng |last2=Misra |first2=Manjusri |last3=Mohanty |first3=Amar K. |date=2021-06-01 |title=Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging |journal=Progress in Polymer Science |volume=117 |article-number=101395 |doi=10.1016/j.progpolymsci.2021.101395 |issn=0079-6700|doi-access=free }}</ref> To prevent water vapor from getting in, an additional layer of PE is added externally.<ref>{{Cite journal |last1=Blanchard |first1=A. |last2=Gouanvé |first2=F. |last3=Espuche |first3=E. |date=2017-10-15 |title=Effect of humidity on mechanical, thermal, and barrier properties of EVOH films |url=https://www.sciencedirect.com/science/article/pii/S0376738817305458 |journal=Journal of Membrane Science |volume=540 |pages=1–9 |doi=10.1016/j.memsci.2017.06.031 |issn=0376-7388|url-access=subscription }}</ref>

Aluminum foil or [[Aluminium oxide|aluminum oxide (AlO<sub>x</sub>)]] coatings are used for packaging that requires a high barrier. Gas transport in these [[Inorganic compound|inorganic]] layers follows the [[Knudsen diffusion]] coefficient Dc, which is governed by:<ref name=”:13″>{{Cite book |last1=Valentas |first1=Kenneth |url=http://www.crcnetbase.com/doi/book/10.1201/9781420049077 |title=Handbook of Food Engineering Practice |last2=Paul Singh |first2=R |last3=Rotstein |first3=Enrique |date=1997-07-23 |publisher=CRC Press |isbn=978-0-8493-8694-7 |language=en |doi=10.1201/9781420049077 }}</ref>

: <math>D_c = \frac{d}{3} \sqrt{\frac{8RT}{\pi M}}</math>

Where d is the diameter of the pore, R is the gas constant, T is the temperature, and M is the gas’s molecular weight. These layers protect effectively, but only if they are protected from pinholes or cracks.<ref name=”:13″ />

== Manufacturing methods ==

Multilayer packaging in industrial production primarily uses three [[manufacturing]] techniques: coextrusion, lamination, and [[coating]]. Each method is used for its capacity to effectively join the material layers into a single cohesive structure, tailored for diverse packaging purposes.<ref>{{Cite web |date=2025-02-19 |title=Multilayer foil extrusion: benefits and applications – BG-plast |url=https://www.bgplast.it/multilayer-extrusion-revolutionizing-packaging-and-industrial-applications/ |access-date=2025-07-10 |language=en-US}}</ref><ref>{{Cite journal |last1=Alreshidi |first1=Maha Awjan |last2=Yadav |first2=Krishna Kumar |last3=Shoba |first3=G. |last4=Gacem |first4=Amel |last5=Padmanabhan |first5=S. |last6=Vinod Kumar |first6=T. |last7=Fallatah |first7=Ahmed M. |last8=Bhutto |first8=Javed Khan |last9=Aldosari |first9=Fahad M. |last10=Alam |first10=Manawwer |last11=Abo El-Khair |first11=Muhammad A. |last12=Tamizhdurai |first12=P. |last13=Subramani |first13=A. |last14=Mangesh |first14=V. L. |last15=Kumaran |first15=R. |date=2025-07-01 |title=Advancements in the production methods and recycling of multilayer plastics with sustainable applications: A comprehensive review |url=https://www.sciencedirect.com/science/article/pii/S1385894725044675 |journal=Chemical Engineering Journal |volume=515 |article-number=163633 |doi=10.1016/j.cej.2025.163633 |bibcode=2025ChEnJ.51563633A |issn=1385-8947|url-access=subscription }}</ref>

[[File:Co_extrusion_for_multiple_polymers.jpg|thumb|318x318px|Co-extrusion for multilayer films]]

===Coextrusion===

This involves the simultaneous [[extrusion]] of numerous [[polymer]] melts via a specially designed die to create multilayer structures in a single, continuous process.<ref>{{Cite web |title=Plastic Co-extrusion Process: What is it And Examples {{!}} Bausano |url=https://www.bausano.com/en/press-and-news/plastic-co-extrusion-process-what-is-it-and-examples |access-date=2025-07-10 |website=Bausano & Figli |language=en}}</ref> This usually involves using a tie layer (e.g., [[maleic anhydride]] grafted [[polyolefin]]) within the molten polymers that [[Interfacial polymerization|interfacially]] reacts to provide appropriate adhesion.<ref>{{Cite journal |last1=Andre |first1=John S. |last2=Li |first2=Bolin |last3=Chen |first3=Xiaoyun |last4=Paradkar |first4=Rajesh |last5=Walther |first5=Brian |last6=Feng |first6=Chuang |last7=Tucker |first7=Chris |last8=Mohler |first8=Carol |last9=Chen |first9=Zhan |date=2021-01-06 |title=Interfacial reaction of a maleic anhydride grafted polyolefin with ethylene vinyl alcohol copolymer at the buried solid/solid interface |url=https://www.sciencedirect.com/science/article/pii/S0032386120309666 |journal=Polymer |volume=212 |article-number=123141 |doi=10.1016/j.polymer.2020.123141 |issn=0032-3861|url-access=subscription }}</ref> This approach enables precise control of layer thicknesses and uniform distribution of materials, which is important for obtaining consistent barrier performance and optical [[Transparency and translucency|transparency]].<ref name=”:0″>{{Citation |last1=Kirwan |first1=Mark J. |title=Plastics in Food Packaging |date=2011 |work=Food and Beverage Packaging Technology |pages=157–212 |url=https://onlinelibrary.wiley.com/doi/abs/10.1002/9781444392180.ch7 |access-date=2025-07-10 |publisher=John Wiley & Sons, Ltd |language=en |doi=10.1002/9781444392180.ch7 |isbn=978-1-4443-9218-0 |last2=Plant |first2=Sarah |last3=Strawbridge |first3=John W.|url-access=subscription }}</ref> Coextruded films generally consist of three to nine layers, while combinations with over fifteen layers exist in specialized barrier packages.<ref name=”:1″>{{Cite web |title=Food Packaging Technology {{!}} Wiley |url=https://www.wiley.com/en-us/Food+Packaging+Technology-p-9781405147712 |access-date=2025-07-10 |website=Wiley.com |language=en}}</ref>

=== Lamination ===

[[File:Lamination_process.jpg|left|thumb|284x284px|Lamination process for a multilayer laminates]]

Lamination is an approach to adhering [[Prefabrication|prefabricated]] substrates, such as plastic sheets, aluminum foils, or paper layers, to form a multilayered structure.<ref>{{Cite web |title=Lamination {{!}} Plastics {{!}} AMETEK Surface Vision |url=https://www.ameteksurfacevision.com/applications/plastics/www.ameteksurfacevision.com/applications/plastics/plastics-lamination |access-date=2025-07-10 |website=www.ameteksurfacevision.com |language=en}}</ref> [[Adhesive]] and thermal bonding are the most common technologies used in industrial lamination. Adhesive lamination is widely used for its versatility in material selection and compatibility; it includes [[solvent]]-based, solvent-free, and water-based adhesive systems that are chosen based on packaging applications and [[Regulation|regulatory]] requirements.<ref name=”:2″>{{Cite web |last=MZ |first=Melody |date=2024-08-06 |title=Types of lamination methods in flexible packaging |url=https://taknamco.com/en/types-of-lamination-methods-in-flexible-packaging/ |access-date=2025-07-10 |website=Taknam Keyhan Polymer |language=en-GB}}</ref><ref name=”:1″ /> Thermal lamination involves heating and [[Pressure|pressurizing]] layers to fuse them without adhesives. It is often used for laminating polymer layers that are innately compatible, such as PE sheets.<ref name=”:2″ />

=== Coating ===

This method is based on applying thin, functional coats to substrates to obtain resistance to moisture, oxygen, UV radiation, and [[Microorganism|microbial]] contamination. Vacuum metallization, plasma-enhanced chemical vapor deposition, and extrusion coating are three standard coating processes used in industry.<ref name=”:3″>{{Cite journal |last1=Wang |first1=Qiankun |last2=Chen |first2=Wenzhang |last3=Zhu |first3=Wenxin |last4=McClements |first4=David Julian |last5=Liu |first5=Xuebo |last6=Liu |first6=Fuguo |date=2022-03-11 |title=A review of multilayer and composite films and coatings for active biodegradable packaging |journal=npj Science of Food |language=en |volume=6 |issue=1 |pages=18 |doi=10.1038/s41538-022-00132-8 |pmid=35277514 |issn=2396-8370 |pmc=8917176}}</ref><ref name=”:9″>{{Cite journal |last1=Kaiser |first1=Katharina |last2=Schmid |first2=Markus |last3=Schlummer |first3=Martin |date=2017-12-22 |title=Recycling of Polymer-Based Multilayer Packaging: A Review |journal=Recycling |language=en |volume=3 |issue=1 |pages=1 |doi=10.3390/recycling3010001 |doi-access=free |issn=2313-4321}}</ref>

* Vacuum metallization adds extremely thin aluminum layers to polymer films, improving barrier characteristics without significantly increasing weight.<ref>{{Cite web |title=What Is the Vacuum Metalizing Process? – Vacuum Metalizing |url=https://www.vacuum-metalizing.com/what-is-vacuum-metalizing/ |access-date=2025-07-10 |language=en-US}}</ref>

* Plasma-enhanced chemical vapor deposition processes deposit ultra-thin transparent [[oxide]] coatings, such as AlO<sub>x</sub> or SiO<sub>x</sub>, onto polymer films for better barrier protection while maintaining transparency. This is useful in food packaging applications that need product visibility with an enhanced gas barrier.<ref name=”:0″ /><ref name=”:3″ />

* Extrusion coating directly applies [[Melting|molten]] polymers onto substrates such as paperboard or films, which is extensively used in carton packaging and paper-based barrier systems.<ref>{{Cite web |title=What is the Difference Between Extrusion Lamination and Extrusion Coating? |url=https://www.yilianmachine.com/news/what-is-the-difference-between-extrusion-lamination-and-extrusion-coating |archive-url=http://web.archive.org/web/20250216092027/https://www.yilianmachine.com/news/what-is-the-difference-between-extrusion-lamination-and-extrusion-coating |archive-date=2025-02-16 |access-date=2025-07-10 |website=Wenzhou Winrich Machinery |language=en-US}}</ref>

== End-of-life management ==

[[File:Aluminium_en_plastic_folie_verpakkingsmateriaal_-_Aluminium_and_plastic_foil_food_packaging_-_The_Netherlands,_May_2020.jpg|thumb|314x314px|End-of-life of multilayer packages]]

{{See also|Plastic recycling|Packaging waste}}

[[Life-cycle assessment|Life Cycle Assessment]] studies on multilayer packaging demonstrate that its lightweight design and barrier characteristics lead to lower overall [[Environmental issues|environmental impacts]] than monomaterial or alternatives.<ref name=”:6″>{{Cite journal |last1=Mousania |first1=Zeinab |last2=Atkinson |first2=John D. |date=2025-06-01 |title=A cradle-to-grave life cycle assessment of multilayer plastic film food packaging materials, comparing to a paper-based alternative |journal=Waste Management |volume=200 |article-number=114747 |doi=10.1016/j.wasman.2025.114747 |pmid=40139046 |bibcode=2025WaMan.20014747M |issn=0956-053X|doi-access=free }}</ref> Cradle-to-gate studies indicate that multilayer films frequently surpass alternatives such as [[glass]] or paperboard laminates in terms of [[global warming potential]] and cumulative [[energy]] demand.<ref name=”:6″ />

However, these functional and environmental advantages are counterbalanced by end-of-life complications. The diverse composition and strong interfacial adhesion of the layers make most traditional recycling methods ineffective.<ref name=”:8″ /> Because of this, multilayer packaging represents over 17% of plastic packaging waste generated in the [[European Union|EU]] annually.<ref>{{Cite web |title=Increasing the quality and rate of MultilayER packaging recycLINg waste {{!}} MERLIN {{!}} Projekt {{!}} Fact Sheet {{!}} H2020 |url=https://cordis.europa.eu/project/id/101003883 |access-date=2025-07-10 |website=CORDIS {{!}} European Commission |language=en}}</ref> Mechanical separation of tightly bound layers like PE/EVOH or PET/Al is currently not possible at scale, and less than 5% of multilayer plastic waste is effectively recycled.<ref>{{Cite journal |last1=Hahladakis |first1=John N. |last2=Iacovidou |first2=Eleni |date=2018-07-15 |title=Closing the loop on plastic packaging materials: What is quality and how does it affect their circularity? |journal=Science of the Total Environment |volume=630 |pages=1394–1400 |doi=10.1016/j.scitotenv.2018.02.330 |pmid=29554759 |bibcode=2018ScTEn.630.1394H |issn=0048-9697|doi-access=free }}</ref> Moreover, [[contamination]] from [[Ink|colorants]], [[Adhesive|adhesives]], and food leftovers restricts [[Recycling|recyclability]] and diminishes output quality.<ref name=”:9″ /> Due to the lack of effective separation or recycling methods, the majority of post-consumer multilayer waste is disposed of in landfills or incinerated, hence compromising circularity objectives.<ref>{{Cite web |date=2020-11-23 |title=Ellen MacArthur Foundation publishes new upstream innovation guide {{!}} Food Packaging Forum |url=https://foodpackagingforum.org/news/ellen-macarthur-foundation-publishes-new-upstream-innovation-guide |access-date=2025-07-10 |language=en-US}}</ref> From a circular economy standpoint, multilayer packaging performs poorly on criteria including recyclability rate, material recovery, and design for disassembly.<ref name=”:8″ /> Recent [[Legislature|legislative]] [[Frameworks (band)|frameworks]], including the EU’s 2025 [[Packaging and Packaging Waste Regulations|Packaging Waste Regulation (PPWR)]], specify that multilayer packaging must be recyclable at scale by 2030.<ref>{{Cite web |last=Vargas |first=Maria |date=2025-06-17 |title=EU’s PPWR: Strategies for Compliance by 2030 |url=https://www.plasticsengineering.org/2025/06/eus-ppwr-strategies-for-compliance-by-2030-009153/ |access-date=2025-07-11 |website=Plastics Engineering |language=en-US}}</ref>

Some recent advancements in multilayer recycling include:

* Solvent-based methods, like CreaSolv and NewCycling, are being developed to selectively extract suitable polymers from multilayer laminates while preserving their performance characteristics.<ref name=”:5″ />

* [[Compatibilization]] techniques are found capable of improving the interfacial adhesion and processability of immiscible polymers in multilayer packaging waste streams.<ref name=”:9″ />

* [[Biochemistry|Biochemical]] techniques, such as [[Enzyme|enzymatic]] [[depolymerization]], are reported to degrade PET. They can also be used for multilayers containing PET.<ref>{{Cite journal |last1=Cheng |first1=Yuhong |last2=Cheng |first2=Yihao |last3=Zhou |first3=Shengcheng |last4=Ruzha |first4=Yelizhati |last5=Yang |first5=Yu |date=2024-09-01 |title=Closed-loop recycling of PET fabric and bottle waste by tandem pre-amorphization and enzymatic hydrolysis |url=https://www.sciencedirect.com/science/article/pii/S0921344924003008 |journal=Resources, Conservation and Recycling |volume=208 |article-number=107706 |doi=10.1016/j.resconrec.2024.107706 |bibcode=2024RCR…20807706C |issn=0921-3449|url-access=subscription }}</ref>

== Smart and biodegradable multilayer system ==

{{See also|Active packaging|Sustainable packaging}}

Multilayer [[Biodegradation|biodegradable]] packaging systems are developing into advanced food packaging solutions that incorporate active functionalities such as [[Antibiotic|antibacterial]] and [[antioxidant]] properties within layered biodegradable structures made for the controlled release.<ref>{{Citation |last1=Saini |first1=Pragti |title=Chapter 13 – Sustainable smart packaging |date=2025-01-01 |work=Sustainable Materials for Food Packaging and Preservation |pages=285–300 |editor-last=Ghosh |editor-first=Tabli |url=https://www.sciencedirect.com/science/article/pii/B9780443135675000137 |access-date=2025-07-21 |publisher=Elsevier |doi=10.1016/b978-0-443-13567-5.00013-7 |isbn=978-0-443-13567-5 |last2=Sharma |first2=Kaustubh |last3=Chauhan |first3=Aditya |last4=Bhati |first4=Sampat Singh |editor2-last=Priyadarshi |editor2-first=Ruchir |editor3-last=Roy |editor3-first=Swarup|url-access=subscription }}</ref><ref name=”:10″>{{Cite journal |last1=Mujtaba |first1=Muhammad |last2=Lipponen |first2=Juha |last3=Ojanen |first3=Mari |last4=Puttonen |first4=Sami |last5=Vaittinen |first5=Henri |date=2022-12-10 |title=Trends and challenges in the development of bio-based barrier coating materials for paper/cardboard food packaging; a review |url=https://www.sciencedirect.com/science/article/pii/S0048969722054274 |journal=Science of the Total Environment |volume=851 |article-number=158328 |doi=10.1016/j.scitotenv.2022.158328 |pmid=36037892 |bibcode=2022ScTEn.85158328M |issn=0048-9697}}</ref> These systems mainly include a barrier layer with an active layer holding functional agents (e.g., [[Phenolic content in tea|tea polyphenols]], [[curcumin]], [[Silver nanoparticle|silver nanoparticles]]), and a control layer to maintain (regulate) the release rate of the active components into food products.<ref name=”:3″ />

Methods including [[electrospinning]], coextrusion, and [[Layer by layer|layer-by-layer]] deposition are used to construct these systems with biodegradable biopolymers such as [[polylactic acid]], [[chitosan]], [[gelatin]], and [[starch]] derivatives.<ref name=”:3″ />

These materials enhance mechanical and barrier qualities while also mitigating sustainability issues by substituting [[petroleum]]-derived polymers. However, broad implementation requires progress in economic production, performance verification in a practical setting, and regulatory conformity.<ref name=”:10″ />

== See also ==

== See also ==

* [[Food packaging]]

* [[Plastic recycling]]

* [[Food packaging|Food Packaging]]

* [[Plastic recycling|Plastics recycling]]

* [[Packaging waste]]

* [[Packaging waste]]

* [[Modified atmosphere/modified humidity packaging|Modified Atmospheric packaging]]

* [[Modified atmosphere packaging]]

* [[Food waste]]

* [[Food preservation]]

* [[Food preservation]]

* [[Food safety]]

== References ==

== References ==

== External links ==

== External links ==

* {{Cite web |title=Multilayer packaging: Innovative and sustainable |url=https://www.extrusion-info.com/articles/1840 |website=Extrusion-Info}}

* {{Cite web |title=Mono-material packaging: a ray of hope |url=https://www.interpack.com/en/Media_News/interpack_Magazin/FOOD_INDUSTRY_PACKAGING/Food_Industry_News/Mono-material,_a_ray_of_hope |website=Interpack}}

* {{Cite web |last=BGPLAST |title=Multilayer extrusion revolutionizing packaging and industrial applications |url=https://www.bgplast.it/multilayer-extrusion-revolutionizing-packaging-and-industrial-applications/ |website= |date=19 February 2025 }}

* {{Cite web |last=EXTRUSION-INFO |title=Multilayer packaging: Innovative and sustainable |url=https://www.extrusion-info.com/articles/1840 |website=}}

* {{Cite web |last=PLASTICSENGINEERING |title=EU’s PPWR: Strategies for Compliance by 2030 |url=https://www.plasticsengineering.org/2025/06/eus-ppwr-strategies-for-compliance-by-2030-009153/ |website= |date=17 June 2025 }}

* {{Cite web |last=INTERPACK |title=Mono-material, a ray of hope |url=https://www.interpack.com/en/Media_News/interpack_Magazin/FOOD_INDUSTRY_PACKAGING/Food_Industry_News/Mono-material,_a_ray_of_hope |website=}}

* {{Cite web |last=Devi |first=Gayathri |title=Multi-Layered Plastics: Why should it be banned? |url=https://www.cag.org.in/newsletters/public-newsense/multi-layered-plastics-why-should-it-be-banned#:~:text=40%25%20of%20the%20global%20plastic%20produced%20is,and%20discarded%20%2D%20making%20these%20single%2Duse%20plastics. |website=Citizen consumer and civic action group}}

{{packaging}}

{{packaging}}

[[Category:Packaging]]

[[Category:Packaging]]